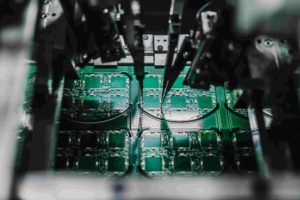

MANUFACTURING

We identify and perform all phases of electronic production.

At Ferrín Electrónica S.L., we work to offer our customers electronic production services that meet the highest standars of quality. Our facilities have the means and the latest generation machinery that allows us to carry out any manufacturing project. This fact, next with our qualified team and our experience of more tan 30 years of activity, allows us to guarantee the success of our products.

Flexible and optimized high-capacity assembly lines that provide support to companies that require mass production, as well as those that need consulting, industrialization, prototyping and start-up of an electronic product.

Our organization works in the constant improvement of the productive processes under the most demanding quality standards of sector.

Two SMD and THT insertion lines ensure the quality and viability of the most demanding delivery times. AOI inspection at 100%.

Two SMD and THT insertion lines ensure the quality and viability of the most demanding delivery times. AOI inspection at 100%.